Heat Mate Induction Heater

Common workshop processes become a breeze including the un-seizing of bolts, track rod ends and ball joints.

The Heat Mate Induction Heater from Hofmann Megaplan is the perfect partner to any of our premium wheel alignment solutions.

- It's fast! Heat Mate takes seconds to heat ferrous based metals.

- It's easy to use! Plug it in, switch on and you're off.

- It's accurate! Finger point accuracy allows for close proximity to heat-sensitive parts.

- It's long-lasting! Water-cooled components mean longer usage times.

- It's safe! The flameless solution means no naked flame or excessive heat.

- It's cheaper! By up to 50% vs. oxyacetylene

Image Gallery

View the embedded image gallery online at:

https://isntest.co.uk/hm2020/products/wheel-aligners/heat-mate-induction-heater#sigProIde394dd1be9

Common workshop processes become a breeze including the unseizing of bolts, Track rod ends and ball joints.

Conditions of Sale | Privacy Policy | Site Map | Copyright 2012-21 Hofmann Megaplan - All Rights Reserved | Design by Eyekon

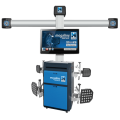

megaline 88

megaline 88 LOGIK 6 Wheel Aligner

LOGIK 6 Wheel Aligner megaline Ssence 600 3D/HD

megaline Ssence 600 3D/HD