Hofmann Megaplan Blog

Hills motors take delivery of their new tyre fitting equipment, with a neat and tidy installation from our engineers.

The Ecomount 22 plus and the Junior Lite wheel balancer are an excellent choice for garages and MoT stations, who cannot justify a premium tyre changer and balancer.

South staffs water have their new tyre changer installed into their workshop.

The megamount 503 Racing builds on the heavy duty structure and premium specification of the megamount 303, yet offers the increased versatility, rigidity and speed of operation offered by the additional pneumatics of a fully automatic machine.

With a heavy duty structure and versatile clamping capability of 10" to 24" (22" external), the megamount 503 Racing offers an incredible price / performance ratio, and this brand new 2014 model boasts an increased column height and bead breaker opening to enable it to handle rims up to 15" wide. The inclusion of our famous 'megafit 2' robotic assist arm ensures full capability with ultra-low profile and run-flat tyres.

As you know by now, the Hofmann Megaplan's ATL MOT site has moved! However that doesn't change the impeccable service we aim to give all the companies we have supplied garage equipment to, and worked with to achieve the best possible result for their MOT Bays.

Our specialist division for handling automotive testing equipment within the workshop, works tirelessly to make sure your ATL MOT workshop operations run efficiently with minimal interruption. We ensure we have individuals with the correct knowledge and skills, working with you on these projects to guarantee maximum productivity and minimum time to delivery and installation of your MOT Testing Equipment.

What do we offer?

Having been a leading supplier of garage and MOT equipment since 1931, our product standards are of the highest quality and we wouldn't supply equipment with the famous 'H' logo on it, if we didn't feel it was up to scratch.

We can supply test equipment for:

Visit Hofmann Megaplan ATL MOT now for more information.

Contact us online or call us today on 01480 891011 to book an appointment with our ATL/MOT specialists.

Smithy Garage motor services have their new tyre equipment installed.

The Ecomount 22plus tyre changer and Junior balancer are an excellent choice for garages and MoT stations who cannot justify a premium package, but need a tyre changer to be able to handle run-flat tyres etc and a balancer that is quick and easy to set up and use. The package eliminates the risk factor in buying an unknown brand for the sake of price.

T Mcquillen motor engineers have their new equipment installed into their busy workshop.

An excellent choice for garages who cannot justify a premium package, but need a tyre changer to be able to handle run-flat tyres etc and a balancer that is quick and easy to set up and use. The package eliminates the risk factor in buying an unknown brand for the sake of price.

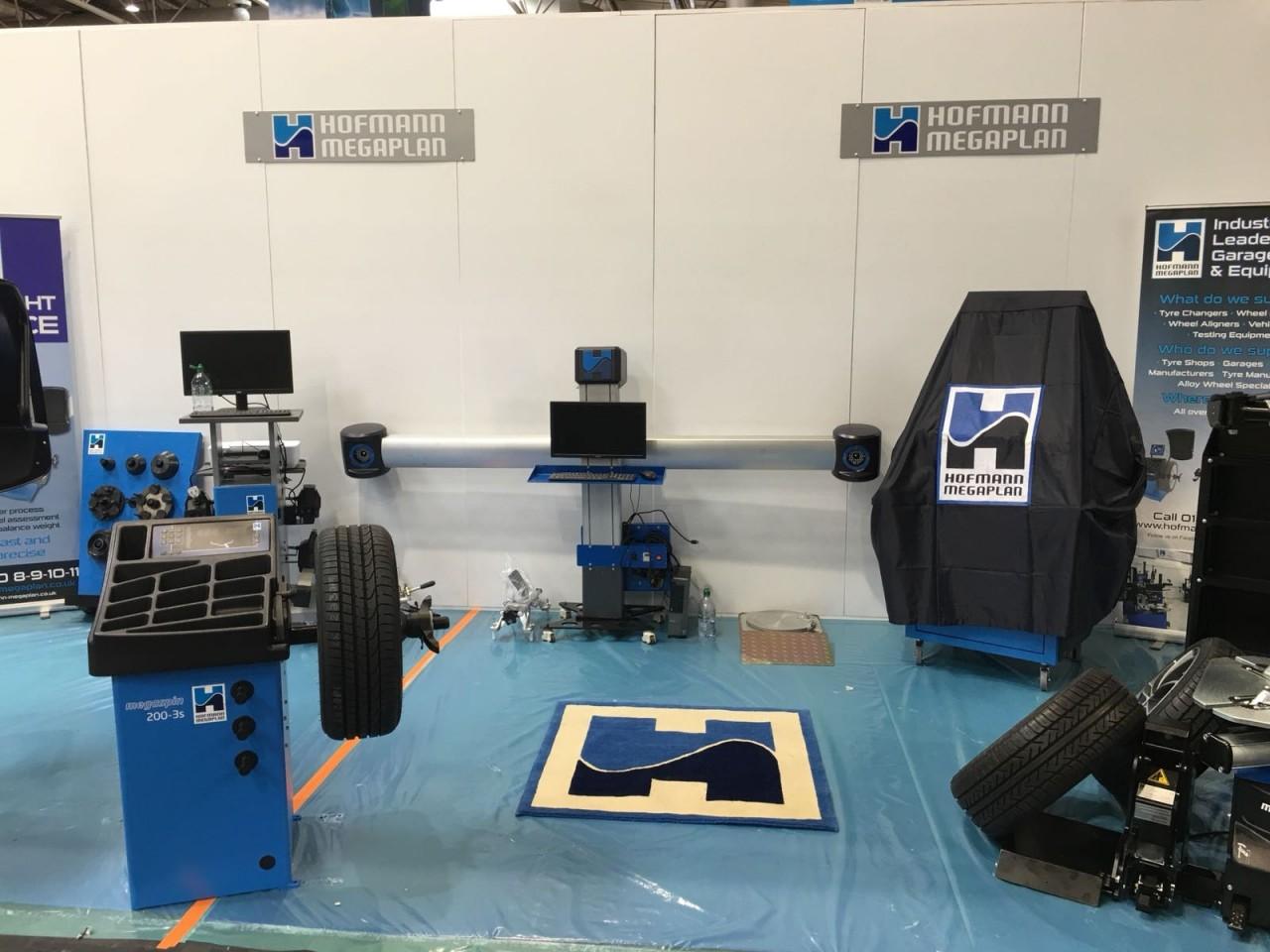

The team at Hofmann Megaplan are pleased to be returning to the Commercial Vehicle Show for 2018 with a Live Demonstration on Stand 4E90.

The CV Show 2018, which takes place over the 24th, 25th and 26th of April is renowned in the industry for being the best-attended event of its kind. Delegates visiting the NEC Birmingham will have the opportunity to see the most comprehensive collection of road transport and commercial vehicle suppliers in the UK.

With close to 21,000 expected to be in attendance, Hofmann Megaplan are pleased to present a live demonstration of their famous 352 truck tyre changer!

It's also a chance to see the great range of commercial products available for purchase now, including truck equipment, dual balancers for truck and van, nitrogen tyre inflation systems and truck alignment machines.

The friendly Hofmann team will be on hand to answer any questions you might have on the day.

Free tickets are still available so don't miss out on this opportunity to meet with sector supplies and see the great showcase of equipment Hofmann Megaplan have on offer at stand 4E90.

You can contact us now by email or request a callback to arrange a time to see the 352 truck tyre changer in action! Live Demonstrations will be happening throughout the 3-day show.

You may have heard a lot of people talking about "old" and "new" gas in the world of vehicle Air Conditioning and wonder what it's all about? Well, firstly, there is no need to panic.

R134a, referred to as the old gas, will not be phased out. It will, however, be regulated and taxed heavily. Newer vehicles are being fitted with Air Conditioning Systems that operate using a new gas known as R1234yf.

Environmental Impact

The change is environmentally driven. More precisely, it is to do with the length of time refrigerants can remain in the upper atmosphere. R134a can take up to 10 years to breakdown into a non-greenhouse gas. About 25 years ago this was considered a vast improvement on R12 which had some 100 years plus life span before it broke down. R1234yf is another step forward in protecting our environment, taking between only three and four years to break down in the upper atmosphere.

You have Time

Relax! Now is the perfect time to train, tool up and offer vehicle air conditioning services using responsible air conditioning tools and systems. R1234yf has only recently been introduced, so there is plenty of time to understand the processes for dealing with the new gas. Currently, around 80% of vehicles will still be on R134a.

With the quick breakdown of R1234yf comes the need to purchase an up to date machine to recover and recycle the new refrigerant. You will also need to understand the new oil compatibility issues with R1234yf and what happens when refrigerants mix.

The performance of R1234yf is very similar to R134a. There will be no major changes to system components. There will however be to the H-block, hoses and the programming in the module that controls the HVAC system.

Your New Air Con Refrigerant

Current prices for the new refrigerant are high, at around double the cost of the old R134a. It's expected that this price will come down significantly in the next few years as production plants around the world ramp up output.

If you are looking to be ready and supply the R1234yf gases, why not look at the two most popular air conditioning units Hofmann Megaplan sell, the Megacool Fast 222YF and the Ermes YF.

Both machines are fully automatic with large 12KG tank capacities. They are suitable for all workshop applications. Please give us a call on 01213 516 329 if you require more information or contact us now on This email address is being protected from spambots. You need JavaScript enabled to view it..

The CV Show 2018 was a huge success with over 50 Live Demonstrations taking place on the Hofmann Megaplan stand over the 3-day event.

Hofmann Megaplan was pleased to return to the NEC once again for the biggest event in the commercial vehicle calendar. As well as live demonstrations the show saw Hofmann showcasing its extensive range of truck equipment including truck tyre changers and wheel balancers.

Representing Hofmann Megaplan at the event was Sales Manager Andy Ringrose, who said "The CV Show once again run a seamless event which was as enjoyable from an exhibitor perspective as delegates.

I would just like to personally thank everyone that took the time to stop by our stand for a chat and to see the 352 Commercial Truck Tyre Changer demonstration. We appreciate the importance of seeing a piece of equipment like this in action which is why we enjoy the CV Show so much and the video we also captured while there. We look forward to more events of the same standard."

The Commercial Vehicle show 2018 took place at the NEC in Birmingham from the 25th to the 27th of April 2018. With approximately 21,000 people in attendance across the 3-day event, it has continued to hold its place as the best-attended event of its kind. You can register for free delegate tickets to the CV Show 2019 now.

Live from the CV Show 2018

352 Tyre Changer Demo | The CV Show 2018 - YouTube

We were at the CV Show 2018 with a live demonstration of the famous 352 truck tyre changer. If you missed us you can get in contact today and arrange a visit.. Andy Currell, Equipment Specialist & Technical Support for Hofmann Megaplan was on hand throughout the event to demonstrate the megamount 352 Truck Tyre Changer. You can see a video above of the full demonstration.

Interested in finding out more?

If you missed us a The CV Show 2018 or are interested in finding out more about the Commercial Vehicle tyre equipment Hofmann Megaplan can provide there are a number of ways to get in touch. You can call us now on 01480-89-10-11, email This email address is being protected from spambots. You need JavaScript enabled to view it. or request a callback.

Our team are always on hand to help advise on the best solutions for your requirements when it comes to providing a first class service in your garage, tyre bay or workshop. You can also visit our fully equipped and working showroom.

I'm going to start this blog series by talking about one of our most common issues those working with wheel alignment equipment can face, and that's turn plates.

If not used correctly, turnplates can cause big problems when trying to achieve a straight steering wheel. Whats worse it can lead you to produce different results each time you attempt to align the same vehicle which quickly becomes infuriating.

Steer Clear of…

Some garages will try and use their MOT plates to save time and these can be ok to just turn the wheel and look for defects. The risk is that they get covered in dirt and that will get into the plate and cause a restriction. To complete an alignment accurately the plates need to be completely free moving.

Others might use their old style dish type turn plates. These most commonly come from an older laser system. They will turn but don't slide, meaning they build up tension and can give you wrong results.

Another common mistake made by alignment engineers is simply not using the pins provided. This is surprisingly common and can cause irreversible damage to your to your wheel alignment system.

Remember to…

We should always drive on the turn plates with the pins in. As soon as you are ready to remove a vehicle from your alignment station, put the pins in. Failing to do this can lead to damage when the car is reversed. The plate can tilt and bearings become loose, impacting the accuracy of your machine.

Some people simply fail to maintain their turn plates. Metal bearing plates will need regular lubrication for example with grease. Nylon bearings don't need any grease or oil but should be cleaned regularly depending on usage by removing the top plate and brushing out any dirt.

As we are entering the winter months, it is becoming more imperative with the colder weather for us to keep track on our tyre pressure. And whether you decide to use Nitrogen or Air, regular maintenance remains critical and necessary.

Why is it necessary?

With every 10 degrees the temperature drops your tyres lose 1-2 PSI. As the temperature gradually declines the likelihood of you noticing such a massive change in your tyre pressure is highly unlikely, however if you don't check, you will begin to see your dashboard light pop up and you will be more liable to punctures.

Nitrogen vs Air.

To combat the loss of tyre pressure, switch from air (oxygen) to nitrogen in your tyres. As Nitrogen molecules are bigger they aren't capable of permeating the rubber like oxygen does, meaning your tyre pressure will remain consistent for longer in the cooler weather conditions. Oxygen also degrades the inner rubber membrane of the tyre that provides a watertight seal, wearing out the tyre faster, and therefore causing you more frequent expenses by replacing them.

You will be required to pay an extra fee for the privilege, nevertheless, you will save money on fuel, part repairs etc. that you will inevitably encounter if you don't switch to Nitrogen.

Contact us online now or call us today on 01480 891011 to speak to one of our specialists, or check out our Nitrogen Inflation Equipment for more information.

5-7 June 2018 | NEC BIRMINGHAM | HALLS 6, 19 & 20

Hofmann Megaplan is pleased to be exhibiting at Automechanika 2018, the UK's leading exhibition for the automotive aftermarket and vehicle production sector.

This year we will have a wide variety of equipment and experts on hand to talk you through every aspect of our machinery.

We will be exclusively showcasing two brand new pieces of equipment. The megamount 813XL is the first tyre changer of its kind in the marketplace; a fully automatic machine, but without the traditional tilt back arm! This Tyre Changer uses an innovative parallelogram design to operate the mounting head with control and precision, removing all flex while fitting.

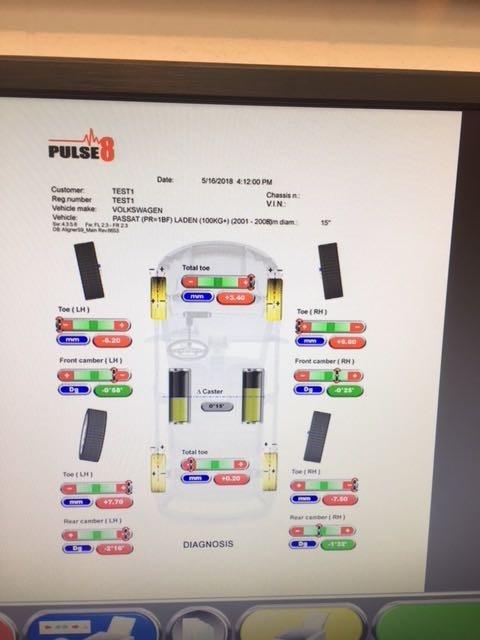

We will also be launching our new wheel alignment system, the Pulse 8. This Italian aligner is changing industry standards! The Pulse 8 from Hofmann Megaplan is the wheel alignment machine that fills the gap between our Ecoline 88 (ccd) and the Ssence 600 HD (3d). This launch will also be accompanied by a new balance program. This will feature on the MS420 and is an OWB program (one weight balance) which is completely new.

Speak to our team at Automechanka to find out more on stand M117 and see images from the show set up below.

Hofmann Megaplan was pleased to see so many delegates from the automotive aftermarket and vehicle production sector at Automechanika 2018.

The 3-day event took place at the NEC, Birmingham and saw Hofmann Megaplan launch a number of new products including the OWB (One Weight Balance) technology for wheel balancing.

It was a record attendance at the show which also saw over 500 suppliers from over 26 countries set up stands in the 3 halls which the event took over.

New from Hofmann MegaplanThe Hofmann Megaplan stand was pushed for space with a wide variety of machines in operation for delegates to inspect. This included the brand new megamount 813xl which proved popular on its show debut. As the first of its kind in the market, this tyre changer is a fully automatic machine but without a traditional tilt back arm.

The Hofmann Megaplan team were on hand to explain to delegates how the innovative parallelogram design operates the mounting head with control and precision, removing all flex while fitting.

Wheel Alignment & Balancing

Alongside the OWB technology for balancing, a brand new wheel alignment system was also available for preview at the show. The Pulse 8 sits between the Ecoline 88 (ccd) and the Ssence 600 HD (3d) and is available to order now. Simply call 01480 8-9-10-11 to find out more now.

Automechanika 2018 proved a valuable opportunity for delegates to see the full range of wheel alignment machines Hofmann Megaplan offers side by side. If you missed out then a visit to the fully operational live demonstration showroom can also be booked by calling 01480 8-9-10-11.

The OWB (one weight balance) balancing software program that will be featuring on multiple machines, including the ms420, ms820, ms1200 and ms2000 was on show at Automechanika 2018. This was its first outing with many delegates impressed at the benefits the system can offer. For more on how OWB works speak to one of our experts today or arrange to visit us for a demo.

In Summary, Managing Director Mark Berryman said of the event "This was an extremely well run and slick operation. I take great pride in any opportunity Hofmann Megaplan has to showcase its incredible range of machines and Automechanika never fails to draw in the right crowd from all areas of the automotive and garage sectors. We look forward to returning next year."

Gallery

Other images from the Hofmann Megaplan team at Automechanika 2018:

The Hofmann Megaplan team celebrated in style this weekend at the companies annual Summer Party 2018.

This year's summer party offered the opportunity to congratulate all staff for what has been the most successful 6-months in the history of the company, making it a phenomenal first half to 2018.

This result is a testament to the knowledgeable and hard working team at Hofmann Megaplan. Their expertise has seen some huge orders across the board secured. This includes the range of tyre changers and wheel balancers that have become the bell-weather of garage equipment in the UK and Europe.

Ever growing in reputation in the same markets are the vehicle lifts offered by Hofmann megaplan. They are lighter, stronger and more robust than the competition. The wheel alignment machines range ensures equipment to suit every budget and requirement of even the most demanding garage or dealership. Add to this commercial equipment, nitrogen inflation and air conditioning machines and the range of garage equipment available and its success within the marketplace are truly great.

On every occasion the sales & scheduling teams have worked in harmony with our skilled engineers to ensure delivery, setup and training have been seamless, leaving customers satisfied every time.

The dedicated sales team, finance, parts, admin and management all had a great time celebrating what is turning into an amazing year for Hofmann Megaplan. Rest assured though, they will all be back ready to take your orders or answer your queries from Monday morning.

Give us a call on 01480 89 10 11 or request a callback.

Following a standard service and adjustment, there is nothing quite as frustrating as putting your alignment system away, only to find customers complaining that the steering wheel isn't straight when the vehicle is driving in a straight line.

This month we are going to look at a very common issue. Its one that regularly turns out to be the cause of misalignment yet is mostly nothing to do with your alignment system at all. However, it is all to do with how you use it. I'm going to tackle the all too common issues with alignment relating to the steering wheel straightness.

Following these steps and tips should help ensure the steering wheel and alignment match up every time:

- Firstly, ensure your machine is correctly calibrated

- Ensure your turn plates are in good condition

- Complete your vehicle pre-checks, I.E Tyre pressures, Tread wear, joint play etc.

- Check to see if you have clean lenses (CCD) or targets (3D)

- Ensure the clamps are fitted evenly around the rim (Ensure run out is done if using uncalibrated clamps I.E. 4 point)

- Always use 4 wheel alignment, not 2! (2 wheel alignment is only suitable for old vehicles where the rear wheels are hidden under arches.)

- You should not be sitting in the car when you put on the steering wheel clamp on. Instead, lean into the vehicle to avoid any change to the bump steer in the car.

- Remember: clamp your steering wheel straight as that is where it will be when driving straight ahead. (Many customers clamp the steering wheel near the end of a castor swing believing the computer is asking you to clamp when straightening the front wheels.)

- Continue with your alignment, bearing the below potential issues in mind.

Post Alignment Check

At the end of the alignment process, and just before you start to remove the heads/clamps, on select systems you are able to click back to the front toe screen in the alignment program. If you remove the clamp and wiggle the steering wheel from side to side, the numbers on the screen should change accordingly. Now try and equal the toe numbers either side. Stand back – the steering wheel should be straight. If not, re-centre the wheel and re-adjust the toe.

Steering Wheel Alignment Issues to look out for:

- When undoing seized or tight lock nuts, the extra force used could move the steering wheel around. It is only the steering wheel clamp that holds the front wheels straight so be careful!

- I've found a lot of customers will heat up locked nuts or track rod ends to get them moving. As we know though, heat expands the metal and this can mean your system will give the incorrect readings. You can solve this by first getting the nut to move freely, then cooling it down with a cloth soaked in cold water. Now make the adjustment. You should be replacing the track rod ends as new MOT laws now forbid the heating of these components

Crabbing

Crabbing is a common term used by mechanics and customers alike, but it should really be referred to as a vehicles thrust line. This is the direction that the rear road wheels/ axle are pointing.

On more basic alignment machines, such as laser or even some computer systems, it is important to check the rear alignment as well. Failing to ensure the rear wheels are in-line with the front may cause the vehicle to "crab". This will mean you'll never get the steering wheel straight. The driver of this car would be turning their wheel to the left just to drive straight!

It is important to understand that the rear wheels are dictating the direction of the car and the front wheels are only compensating to keep the vehicle straight or steer. This is why it is important to find the thrust line and compensate for it when using lasers.Note: Most modern computers will compensate for this issue.

As a provider of wheel alignment services, chances are you know the advantages this service brings to your business but have you got the patter down on how to convey the benefits of alignment to your customers? Read on to find out the main arguments to put forward when someone is hesitant to sort their alignment.

Burning money on new rubber

New tyres can be costly. On average you can pay £110 per tyre so 4 tyres would be equivalent to a week's average wage. Depending on how bad the vehicle's alignment is, your customers could be wasting a tyre for every 4 you fit! They may try to blame the standard of tyre used or the quality of your job but it is important that they understand tyre will be subject to far more damage under the stresses of misalignment.

The car performs as intended

Mis-alignment means a car does not perform as it would have when driven out of the factory. Responsiveness in the steering will be impacted and the handling will suffer because the tyres will be struggling to do their job. Completing alignment checks and adjustments will help keep the vehicle on the road. Neglecting to do so is putting all the occupants at risk.

Improved Fuel efficiency means real savings

Many vehicle owners will often complain that their car seems to get through fuel quicker and quicker, but they do not realise how correct alignment can help a tank go further. Imagine having to push a car up a hill. Obviously, you're going to use much more energy than you would on a flat surface.

Effectively that's what your car is having to do when the alignment is out! The more you accelerate, the more fuel and power is needed to reach the same speed.

More than just wheels need replacing

It's not just the wheels that misalignment can wear away. As cars have gotten more advanced, the cost of components has also increased. Replacing wheel bearings with built-in speed sensors can cost a good few hundred pounds to buy and fit. Why do they need replacing? Because bearings get hot and wear prematurely due to miss alignment.

The same also applies to the bushes and joints on your car as they are having to work much harder simply to drag your tyres down the road. Expensive right?!

What can you do for your customers?

Just as the team at Hofmann always seek to advise our customers to ensure they get the most out of their tyre machines and garage equipment, you too can advise your customers and educate them as to why alignment is so important based on the above.

It is common practice to recommend your customer check their wheel alignment and have it adjusted as needed every 10,000 miles or at every service, whichever happens first.

Author | Warren Carr | Wheel Alignment Specialist

My name is Warren Carr and I'm from the team of alignment engineers at Hofmann Megaplan. I will be using this blog to regularly highlight some practical hints and tips which will help you, our garage professionals, achieve great results with your equipment, no matter the make of alignment machine.

Hofmann Megaplan's ATL MOT site has moved! You can now find all our MOT Bay and Automated Test Lane equipment on the main Hofmann Megaplan website.

ATL/MOT is our specialist division for handling automotive testing equipment within the workshop. The specialist team works tirelessly to make sure your workshop operations run efficiently with little interruptions right from the planning stage. We have individuals with expert knowledge and skills working on projects to guarantee the perfect bespoke bay for your garage.

Why have we moved MOT Bays & ATL?

For ease of use! Moving our ATL MOT products onto the main site helps you see the full range on offer when looking to spec your garage out for new equipment, from lifts to MOT Bays, Tyre Changers to AC recovery machines.

Can you still find the same products?

Absolutely! Nothing has changed in regards to our product range.

We still supply the same industry-leading equipment and services to make sure everything is working properly and runs smoothly.

Our specialist engineers liaise with you during the planning, execution and post-installation phases of the project, to deliver reliable test lanes that generate consistent results, and dependable income.

Equipment:

Products:

Services:

What are you waiting for? Visit Hofmann Megaplan ATL MOT now!

Do you need more information or advice on what we can do to help your workshop? Contact us online now or call us today on 01480 8-9-10-11 to book an appointment with our MOT Station specialists.

A spot of ingenuity from our engineers at this recent install in Kam Servicing in Heanor.

There was a limited amount of space to work with, but we successfully managed to install a Megamount 603 tyre changer and a Megaspin 420 wheel balancer. The main concern was making sure they didn't get in the way of the doors or each other, and we managed to create the perfect fit. Both machines are able to operate seamlessly in tandem without disruption to the other.

The above image shows how we were able to make the most of space we had for the install whilst minimising the tyre equipment's overall footprint in the workshop.